Gfeller Casemakers is a producer of fine leather goods in Meridian, Idaho, with a long tradition of excellence. I met Steve Derricott, the owner of Gfeller (pronounced with the G) on a chilly winters morning at his shop in Meridian. I had a great visit as Steve game me a history of Gfeller and we discussed his product line and his continuous commitment to quality.

My first impression of his shop was that this is a true leather craftsman’s shop. Upon entering, you are immediately welcomed by the scent of freshly worked leather. You notice that many of the workbenches and shelving are custom made. Many of the tool sheaths were made of fine leather by Steve himself. His polishing and burnishing wheel, for example, needed a custom cover and Steve created a beautifully tooled and formed leather. Why buy when you can make?

history

Gfeller Casemakers was founded by Roy Gfeller in 1946 in Colorado. A saddle maker by trade, Roy’s proximity to the United States Geological Society prompted a request for him to create some custom cases for geologist field gear. It was imperative that these cases could withstand some serious use and abuse and would not break down. Roy became known for using the highest quality materials, and producing the highest quality goods. Upon Roy’s passing in 1985, Gfeller became available for purchase. Steve Derricott heard of this and after some inquiry and time spent at the company, purchased the company and moved it to the Boise, Idaho area. The timing was perfect for Steve. As a geologist himself, and as someone who had used Gfeller products, he was ready for a change and ready to spend less time on the road. Steve made a decision at that time to stay committed to Roy’s standard of quality. Steve was able to expand the business, and branch out into other high quality leather products.

product line

Gfeller Casemakers has three general product lines: geoscience bags and goods, notebooks and small personal items, and custom leather goods. Gfeller has been secured as a maker of fine goods by the likes of Chris Reeves, Tegam, West Point, and others. They make custom knife sheaths, tool carriers, saber belts, cartridge boxes, etc. Steve has made a conscious decision to stay away from horse tack and sporting goods. Steve has provided the opportunity for BestLeather.org to review a couple of his products, a notebook cover and an iPhone 5 case. Reviews for those two products will be posted soon.

commitment to quality

One of the things that I admired the most with Gfeller was their commitment to continuing Roy Gfeller’s tradition of using the highest quality materials and the best processes, in order to produce the best product. It’s the type of thing that we at BestLeather.org love to see. Upon acquiring Gfeller, Steve made the decision to use the Hermann Oak Tannery for all of it’s leather. Hermann Oak has long had a tradition of producing fine finished leather. Many of the goods we have reviewed at Best Leather use Hermann Oak leather as well, in fact.

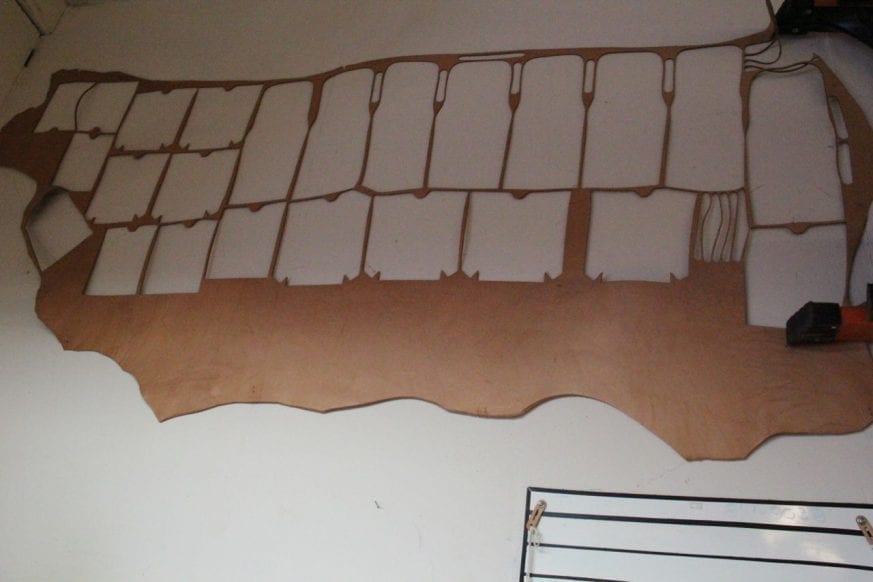

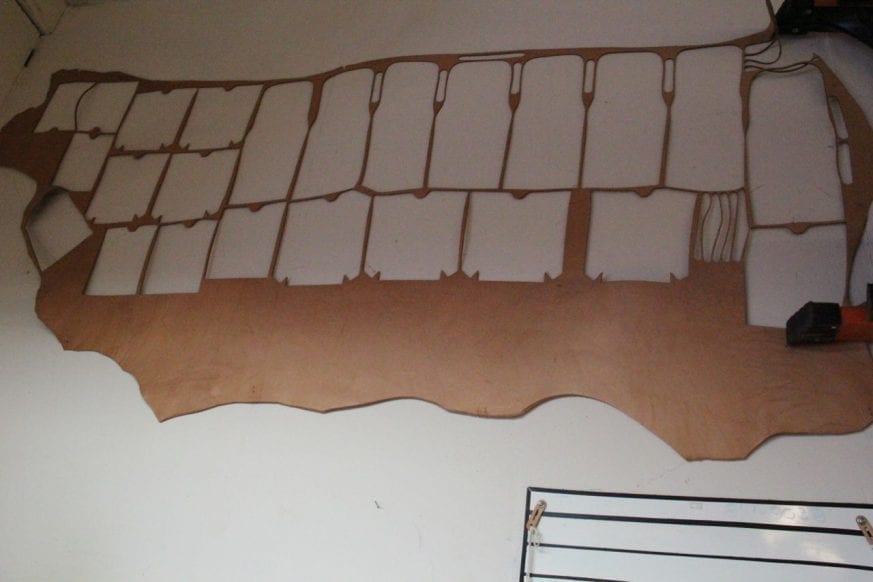

This fact is no coincidence. Part of the reasoning for this choice was consistency and efficiency. Using the same high quality tannery results in consistently getting high quality leather, which Gfeller customers demand. Also, using leather from the same tannery increases efficiency. Gfeller is able to use pieces from different hides in constructing different bags and products. This efficiency reduces waste and saves money, which allows Gfeller to sell high quality products at reasonable prices.

Another interesting conversation that I had with Steve related to the type of thread they use for their bags. On all of their geoscience bags, Gfeller uses linen thread, like Italian fine leather shoemakers. Many high quality leather goods makers currently use synthetic threads for their bags, mostly polyester and nylon. Like Roy Gfeller before him, Steve has chosen linen thread as a matter of appropriateness. Linen, as it turns out, is a good match for leather, strength for strength. Polyester thread can actually tear through leather stitching, linen is not likely to do so. A look at a wall full of old Gfeller bags, at the Gfeller Casemaker’s shop, shows that this thread can pass the test of time, just like fine leather. I appreciate this attention and thought to detail. It’s this attention to detail and good business practices that has kept Gfeller thriving.

business practices

It goes without saying that a quality leather good doesn’t become that way by chance. Gfeller’s reputation for high quality goods depends on it’s adherence to best practices and efficiencies. For example, Steve pointed out to me, quality assurance is as important as, if not more important that, quality control. Quality assurance demands maintaining quality throughout the production process. If a defect of some sort is discovered during the production process, the defect is fixed or discarded immediately. This ensures that quality control is a breeze.

Steve also devotes considerable attention to utilizing the most appropriate machines in production of Gfeller’s goods. The tool, or machine used, makes all of the difference in the efficiency of one’s operation. At Gfeller’s, you’ll find die presses, industrial sewing machines, polishing wheels, hand tools, etc. These tools were all acquired to increase efficiency, maximize man hours, and allow Gfeller to offer high value in the products they sell.

BestLeather conclusion

My visit to Gfeller’s shop gave me a greater appreciation for the work of fine leather craftsman. Steve Derricott is a man devoted to maintaining a tradition of excellence. This was evident from the hand made tool sheaths, to the perfectly punched hide hung on the wall, to the fine leather cases and goods being made to order.

You can visit Gfeller Casemakers Website by clicking here.

Below is a series of photos documenting the process of completing a Gfeller compass case, from soaking in water to burnishing, cleaning up with a deer antler to forming, riveting, oiling and done.

Steve, thank you very much for your time and open access to your operation! Very enjoyable!